Altium Plated Slots

Read about 'How to define milling slot in altium' on element14.com. Hi I need a little help about one thing that I have been thinking around for a while. I decided to precut the perimeter of my board by putting milled. Slot - specifies a round-ended, slotted hole for this pad. Slotted holes can be plated or unplated. Separate drill file (NC Drill Excellon format 2) are generated for each hole kind, as well as for plated and non-plated holes. There are up to six different drill files for these types.

Spotting some common PCB design mistakes will help get your board into production faster

I’ll admit that I was not an excellent student until I hit graduate school. At that point, I started putting more energy into my homework than most other areas of my life. Sure, my social life became non-existent, but I soon became an exemplary student and I never looked back.

Generate separate NC Drill files for plated & non-plated holes - check this option to create separate drill files for plated and unplated holes. Use drilled slot command (G85) - check this option to use multiple drilled holes to create slots. Best Practices for Plated Slots We see a lot of different footprints and component types for PCB Assembly at Bittele Electronics. A majority of through-hole part footprints are designed with circular holes to accommodate circular or square leads.

Just like you need to do your homework while in school, you should do your homework before sending your new design off to a manufacturer. There are some common errors that can pop up in any new design, but you can avoid these problems by closely checking your layout and Gerbers before sending your design off for manufacturing. Checking for these points helps you avoid a no-bid response from your manufacturer and helps increase yield after assembly.

Common PCB Design Mistakes Before Fabrication

Manufacturers that are worth their invoice will take time to check some key points before beginning a fabrication and assembly run:

Component availability, cost, and obsolescence

Match between schematic, layout, Gerbers, bills of materials, and Excellon files

Conformance to the manufacturing process

The first point above requires looking into the supply chain to ensure your components can be sourced within your budget. Checking for obsolescence also ensures your product will have the longest relevant lifetime. Doing this homework assignment on your own, and doing it before you create your schematic and layout, reduces the risk of a redesign and decreases the overall production time.

The second point involves a direct comparison between your design documents. You want to make sure that every drill hole appears in your Gerbers and your drill files. You should also check that every component in your schematic/layout appears in your bill of materials. Some CAD programs will create individual files for every board layer, and its is the designer’s responsibility to ensure that every file required to manufacture a board is prepared and accurate.

The third point really relates to the second point. Manufacturers will typically examine your Gerbers and Excellon files to ensure your design can be produced at full-scale with their processes. Features may look excellent in your layout and your Gerbers, but they may not appear in the same way you imagined (if at all) in your finished product. As a designer, you should consult with your manufacturer or a manufacturer’s representative regarding their capabilities and requirements.

Here are some common PCB design mistakes you can spot if you carefully examine your Gerbers and your layout.

Overlapping or Misplaced Drill Hits

Overlapping two drill holes to try and create a slot is a recipe for disaster. There is an extremely high chance that the bit will break during drilling. Instead, you can use the codes in the Excellon drill tables that will define this particular feature as a slot. Similarly, misplaced drill spots for vias can hit a trace or pad on a surface or inner layer, which will destroy the copper feature.

Both mistakes can be located by turning on all your layers in your PCB layout during your DFM check. With relatively simple designs, your manufacturer can simply move the via for you as this is unlikely to affect functionality. In more complex designs, your manufacturer will be (or should be) hesitant to move any drill holes or vias for you as many more complicated changes may be required. Your design might be sent back to you for changes before your board can be sent into production.

Do you know how to determine the return current path in this PCB layout?

Solder Mask Clearances Around Pads

Soldermask errors are surprisingly frequent. In some cases, the manufacturer can fix these errors during a design review. In some cases, especially with HDI designs, the manufacturer will send your design back for modification. This will allow to see where your solder mask has accidentally covered pads, holes, or vias. Conversely, solder mask clearances around pads can be oversized, causing nearby copper traces on the surface layer to peek through the solder mask.

Traces are surface-finished (e.g., with ENIG) before applying solder mask, thus the issue with exposed traces is not one of potential corrosion. Rather, the danger with exposed traces around SMT pads involves assembly, particularly reflow soldering. There is a danger in bridging between a pad and a nearby exposed trace, or between two adjacent exposed traces, when the solder mask clearance is too large.

Fixing solder mask errors is simply an issue of turning on all your layers during a design review. Something as simple as zooming into your Gerbers and carefully checking solder mask openings before sending your design off to your manufacturer can prevent a long delay. An experienced manufacturer may notice this immediately, but novice overseas manufacturers may start producing boards without a second thought about your solder mask.

Watch for solder mask clearances

Super-high Aspect Ratio Blind and Buried Vias

Blind and buried vias are extremely useful for routing between multilayer boards with high layer count. In HDI boards, blind vias on one side the layer stack are useful as they eliminate the need for through-hole vias that span the entire layer stack. This isn’t meant to disparage blind vias; the message here is to use them judiciously and keep an eye on the aspect ratio of your vias.

The conventional wisdom regarding blind/buried vias is that they should only span a single layer. If you need to span multiple layers, then you’ll need to use stacked blind/buried vias. However, some CAD tools will allow you to define a blind via that spans any number of layers, and even through the core of your board. In other words, some CAD tools do not limit the aspect ratio of your blind/buried vias.

High aspect ratio vias may cause your design to receive no-bid status, particularly when attempting to route through the core of your substrate. If you do need to route between multiple layers in a high layer count board, you’re better off using stacked blinds/buried vias for two reasons. First, blind/buried vias need to be plated just like any other via. A larger aspect ratio via can be more difficult to plate throughout the entire via, leading to thinner copper deeper into the via hole. A via with a larger diameter can generally be plated deeper into the via hole. At some point, the via diameter becomes so small that your costs begin to increase as the drill size required to place the via will become so small that it breaks easily during manufacturing, thus laser drilling is used.

Pay attention to your via aspect ratio

The highest aspect ratio blind via you should use in your board depends on the diameter of your via hole. For larger diameter vias (~10 mils), some manufacturers will place blind vias spanning multiple layers only as long as the aspect ratio does not exceed 2 or 3. Smaller diameter blind/buried vias with similar aspect ratio must be limited to spanning fewer layers. At some point (as long as you are not in the microvia regime) you are better off simply using through-hole vias with more creative routing.

The powerful PCB design and analysis tools in Altium Designer can help you analyze all aspects of your schematics and layout. You’ll also have a complete set of tools for preparing deliverables for your manufacturer. These tools are built on top of a rules-driven design engine, allowing you to perform important verification steps throughout the design process.

Now you can download a free trial of Altium Designer and learn more about the industry’s best layout, simulation, and production planning tools. Talk to an Altium expert today to learn more.

It is a very common misconception for beginners (and even some experienced) board designers to just push the “buttons” or menu “commands” in the software for outputting fabrication & assembly data. However, there are set-ups that have to be done before you can use those buttons and commands. (Altium Designer® commands highlighted in RED below.)

While there are many ways to develop documentation for a board, it is important to realize the need to give separate information to each manufacturing process. The data needed to produce your board by the Fabricator is different than what is needed by the Assembler. So, first, let’s define what type of data each of these manufacturers really need. Please note that the setup for the data must be done in the design package even if you create an ODB++ file OR you use the IPC-2581 outputs. Remember – GIGO. (Garbage In, Garbage Out)

Fabricator needs to know the following details

These are presented in a FABRICATION DRAWING and accompanied by a set of processing files. The FABRICATION DRAWING can be done using Draftsman® and the processing files can be set up in the Outjob. These can all be ZIPPED into one package for the Fabricator. (A quick search on AltiumLive will give you many options for details on using these commands.)

Size of the Board and location of features

This includes defining an ORIGIN (0,0 point) where all dimensions can be measured and verified. NC Drill files do NOT do this for you. Neither does creating an NC route file (although these can be very useful to the fabricator).

- Dimensions for the overall boundaries

- Dimensions for cutouts & notches

- Dimension for the overall Thickness of the board

- Use GDT tolerancing methodologies.

Holes & Slots

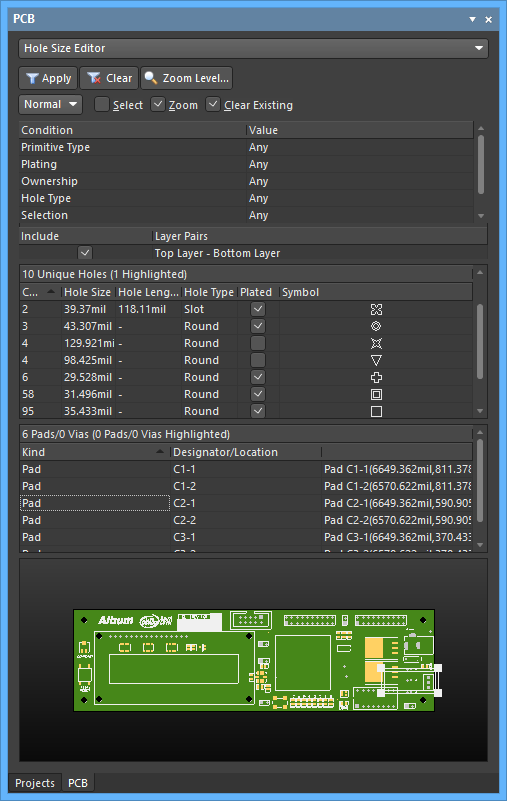

This is best shown with a Drill Table and produced with an NC Drill File. (Check hole sizes with Panels/PCB/Hole Size Editor.)

- Number of different hole sizes. These should be in increments of 2 mils (0.05mm) for consistent, cost effective results.

- Definitions for Plated, Non-Plated, and depth (Blind, Buried, and back drilled).

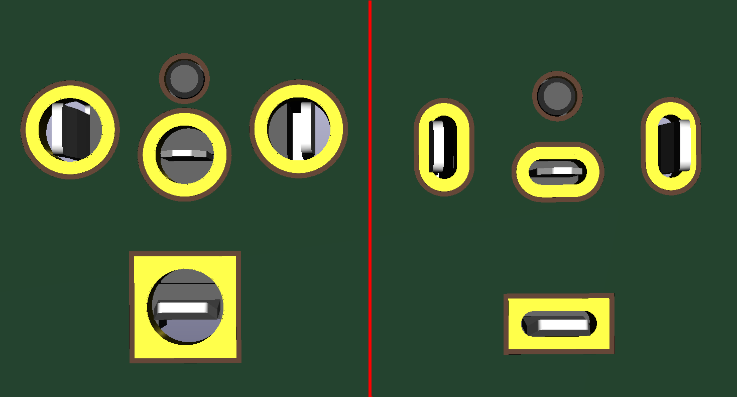

Figure 1. Drill drawing view

Number and definition of Layers

This includes a GERBER for each process layer – copper, gold plating (if present), soldermask, and silkscreen. (Setup should be done in the Layer Stack.)

- Show a Layer stack and define where the signal and plane layers are. Number the copper layers to prevent confusion. Name the Top & Bottom soldermask & silkscreen layers and any other additive process layers.

- Thickness and material can be generic or specific depending upon your needs.

- Some companies also show a view of each copper layer.

- This isn’t really necessary but can help to quickly identify the “positive or negative” nature of the GERBER file. Many programs will produce “PLANE” layers as either a “positive” or “negative” image.

- It can also be a quick reference for the designer or design team to be sure all expected features have been defined correctly in each layer.

Figure 2. Layer Stack

Figure 3. Gerber Views

Test Point locations for fabrication or a list of the files included with the documentation.

After defining features in the layout as a Fabrication Test Point, you can export these in the IPC-D-356a Netlist file. (Set up in Outjob/Fabrication Outputs.)

- Sometimes the fabricator will want to have a copy of the Schematic to verify some of the nets. Depends on what requirements are being asked of the fabricator to ensure electrical features such as differential pairs and continuity through net-ties.

Provide Notes for:

- Tolerancing, manufacturing processes, and IPC product classification (helps to define the tolerances).

- Plating requirements

- Registration

- Soldermask material & color

- Silkscreen material & color

- Any special coatings or finishes (Conformal coating materials, gold plating, HASL, etc)

Figure 4. Fabrication Notes

What the Assembler Needs to Know

All the information that the assembler needs to know are presented in an ASSEMBLY DRAWING and accompanied by a set of processing files. The ASSEMBLY DRAWING can be done using Draftsman® and the processing files can be set up in the Outjob. These can also be ZIPPED into one package for the Assembler.

View of the intended Assembly of the board from Top, Bottom, and side

- If there are variants of the assembly, they should be noted in the view(s). This is where you SHOW which components don’t get installed and which ones do.

- Also, a quick reference dimension of the overall size (X & Y) of the board and a dimension of the height of the tallest component(s) on each side of the board.

- This gives the assembler a good quick reference to the type of machinery they will need to produce your boards.

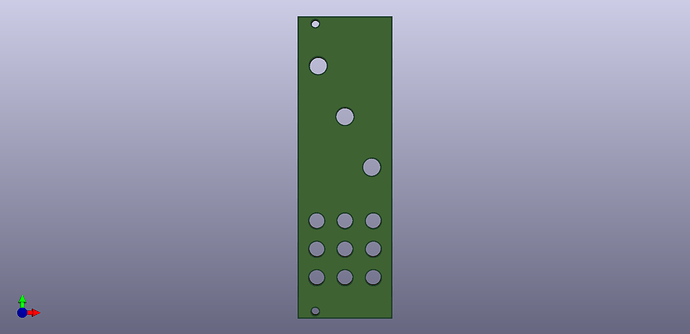

- A 3D view is nice, but not always necessary. A 3D view is to clarify assembly intent and facilitate good communication.

Figure 5. Assembly View

Figure 6. Assembly view from the side

Define the placement/alignment variables/tolerances for components that must interface with other mechanical features in the completed part (such as an instrumentation panel, switch or button interface, or light pipe).

Use the same origin used in the fabrication drawing to define these location tolerances.

Use GDT tolerancing methodologies for X, Y, & Z locations.

Use details to assist with alignment accuracy if needed.

Provide a Pick & Place file from the layout

- This is a generated text document with origin locations of each component. It is used in the set-up of the assembly machinery. The file lists the component locations relative to the PCB origin.

- NOTE: All SM components are placed (and thus referenced for location) using the CENTER of the part, not an edge! This is due to the type of placement machinery used – a suction tube robotic arm. Many TH components (or heavy components) are placed using a “grabber” type of robotic arm. Their location reference may be “Pin 1” or may be “body center”. For headers & TH connectors, use “Pin 1”. When there is a mix of SM & TH in the same part, use the body center.

Provide a BOM with approved second & third sourcing for components

This can be included on the Assembly drawing or as a separate document. BOM output can be done from either the schematic or the layout. There are many ways to produce a BOM.

Don’t leave alternate components up to the Assembler. Many components look the same and are NOT. All alternate components should have the same FORM, FIT, and FUNCTION!!

Figure 7. Bill of Materials

Provide NOTES for:

- Tolerancing, manufacturing processes, and IPC product classification (helps to define the tolerances).

- Special component programming requirements.

- Additional assembly procedures AFTER soldering.

Figure 8. Assembly Notes

Define Assembly Test Procedures

This also can be included on the Assembly drawing or as a separate document. Options can include:

- Include Functional test requirements as needed.

- Provide a test program file if needed.

- Define assembly test points.

- These should be located away from component soldering joints and outside of all component bodies.

- They should be on a grid if using “bed-of-nails” test procedures. Specify the grid used.

The issues we all face while doing the set-up for Fabrication and Assembly files and documents often lie in just a few places. Look at the workarounds vs “good practice” methods being used in your environment and consider what can be improved.

Have more questions? Call an expert at Altium or read more to gain a deeper understanding of sending a complete documentation package to PCB fabrication with Altium Designer®.

Altium Plated Slots Coins

Team Up and Save

Altium Plated Slots Machine

Get Special Savings When You Add a New Altium Designer® Seat